Following years of research, Teysha Technologieshas developed a natural polycarbonate platform that can create fully biodegradable substitutes for existing petroleum-based plastics. The bioplastic, AggiePol, is derived from sustainable feedstocks and can be physically, mechanically and chemically tuned to suit the needs of its intended application. The versatile material could replace the traditional plastic used in the automotive industry and medical equipment.

Teysha’s technology uses a plug-and-play system that takes monomers and co-monomers, the natural building blocks of plastics, to create an eco-friendly alternative to traditional polymers. Instead of using hydrocarbon-based petrochemicals, which are sourced from fossil fuels and generate various pollutants in the manufacturing of the material, Teysha’s platform uses natural products such as starches and agricultural waste products.

By controlling the chemistry, formulation and polymerisation conditions, the polycarbonate materials created can be precisely tuned. Unlike existing bioplastics such as PLA and PHA, the degradation rate of AggiePol can also be tuned, minimising the environmental impact of plastic products after the end of their useful lifetime.

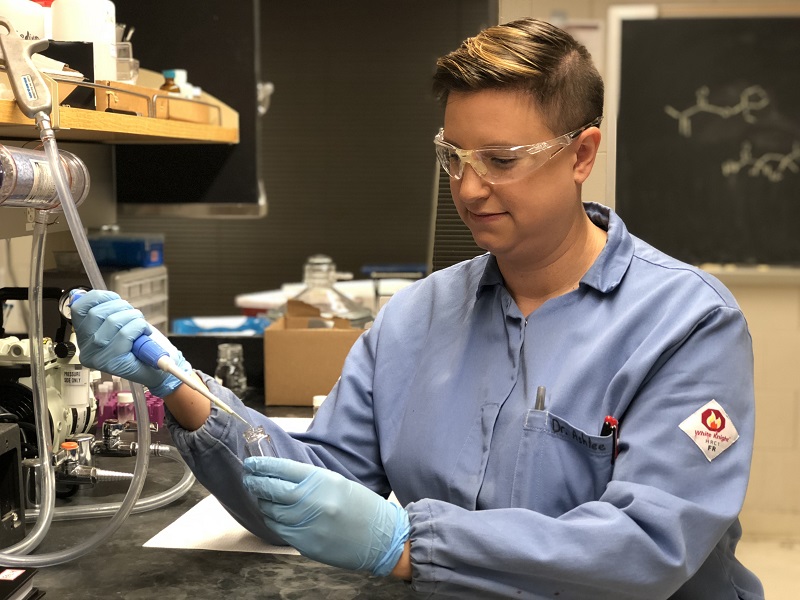

“In the sea, existing plastics often break down into microplastic particles that can be consumed by marine life and ultimately work their way up the food chain and end up on our dinner plates,” explained co-inventor and head of research at Teysha Technologies, Dr Ashlee Jahnke. “The ultimate fate of plastic materials and whether they breakdown must be taken in to consideration, as many plastics can persist in the environment or landfills for thousands of years.

“At Teysha, we have developed a system where the main mechanism of polymer degradation is water-driven. This allows for breakdown in any environment containing sufficient moisture and not necessarily requiring microbial activity or industrial composting conditions.

“Until now, strategies to reduce plastic pollution have relied on changing human behaviour, such as encouraging recycling and banning certain plastic items like carrier bags. By considering the ultimate fate of an applications material in the initial design stage, we can reduce the environmental impacts that occur from plastics, even those made by natural products, and stop contributing to the long-term accumulation of plastics in our oceans.”

It’s estimated that there is currently around 80,000 tons of plastic in the Great Pacific Garbage Patch alone. As the growing demand for single-use disposable plastic products such as packaging increases, finding a substitute like Teysha’s AggiePol has never been more critical.

Teysha Technologies is also currently working to use green and sustainable manufacturing processes, such as carbon dioxide capture and reagent recycling, for the synthesis of all its polymer building blocks.

Sources: https://www.engineerlive.com/content/breakthrough-biodegradable-plastics