where sustainability meets innovation

A Sweet Solution to Plastic Pollution

What We Offer

Teysha's sustainably sourced, second-generation bio-polymers replace traditional, environmentally damaging petrochemical plastics in a wide range of applications.

our mission

Our mission is to promote sustainability and reduce environmental impact by providing high-quality Teysha products as alternatives to traditional plastics through innovation and collaboration.

Join us in our commitment to a cleaner, greener future with our innovative Teysha solutions.

Environment Sustainability

Reduced Carbon Footprint

Versatility

Versatility

Easy to Adapt

Easy to Adapt

Circular by Design

Our Polymers

Our polymers are diverse in properties and, therefore, diverse in their utility. Teysha welcomes enquiries about sampling our products to test in customer applications.

Our patented products are brand new to the market; therefore, the full range of applications is yet to be discovered.

System

Plug & Play

System

Plug & Play

"The ocean faces global warming, pollution, and acidification, risking ecosystem collapse. With over 3 billion people dependent on it, urgent action is critical."

Mary CreaghUK Nature Minister

“When you consider the magnitude…We need people to contribute, to do their fair share and to recognise the opportunity that we have to work together."

Jake Levine National Security Council, The White House

"Once in the sea, plastic remains for decades or centuries. Without quick action, our oceans will soon be dominated by plastic, a prospect that is deeply concerning."

David Attenborough Explorer, Broadcaster, Natural Historian

"The global plastic pollution crisis can only be addressed if all these measures are included in the treaty.It is now up to the countries that want a strong treaty to ramp up ambition and make this a reality.”

Eirik LindebjergGlobal Plastics Policy Manager - WWF

“It is the worst of times but it is the best of times, because we still have a chance”

Sylvia EarleNational Geographic Explorer

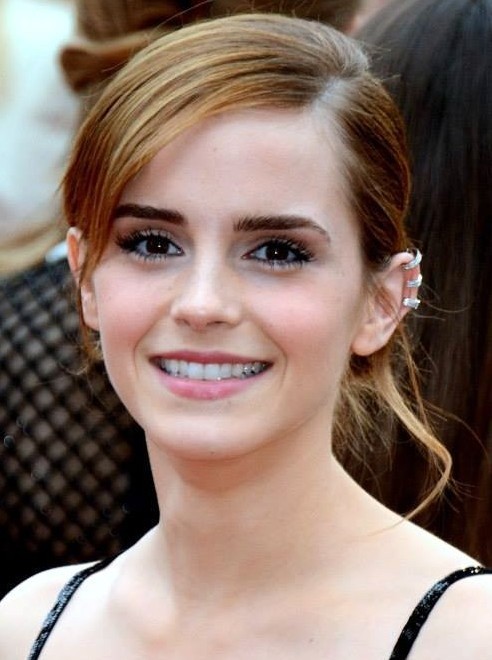

“As consumers we have so much power to change the world by just being careful in what we buy”

Emma WatsonActress & Environmental Activist

“The greatest threat to our planet is the belief that someone else will save it.”

Robert SwanExplorer & Global Environmental Activist

“Over-production of plastic is undermining everything else that we are trying to do downstream”

Christina DixonActress, Writer & Producer

Subscribe to our newsletter

Subscribe to our newsletter

Plastic Revolutionized, Nature Harmonized.

Learn more about the technology behind Teysha by scanning this QR code.

Plastic Revolutionized, Nature Harmonized.

Learn more about the technology behind Teysha by scanning this QR code.