Embark on a chilling journey into the shadowy world of microplastics, 4.5 million tonnes of which silently infest our oceans, evading human sight yet leaving a haunting mark on our planet.

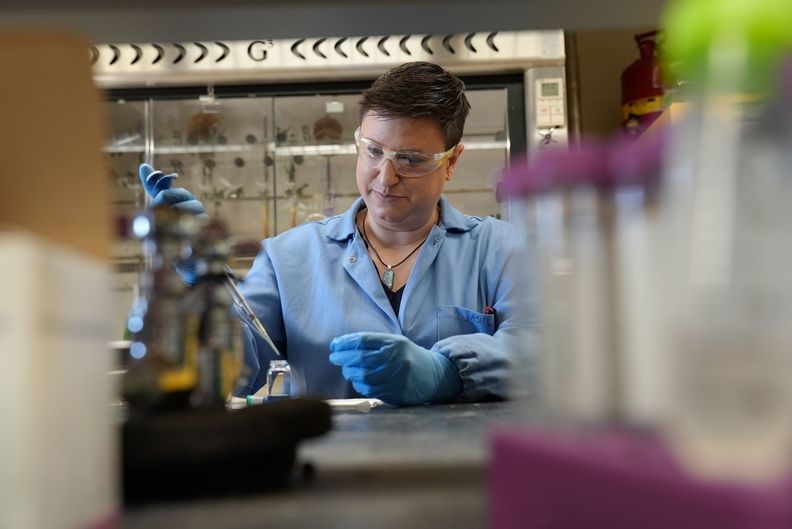

Here, Dr. Ashlee Jahnke, head of research and development at biodegradable biopolymer developer Teysha Technologies, unveils the reality of these unseen pollutants and introduces innovative biopolymer solutions that promise to exorcise the environmental spectre of microplastics.

A microplastic is any plastic with a diameter of less than 5 mm, or the equivalent of a sesame seed. They come from a variety of sources and are best known for their impact on the environment. In the ocean, for example, microplastics have become increasingly widespread, even being found hundreds of miles away from the closest human civilisation.

Microplastics can impact global wildlife in numerous ways, including changing animal behaviour. In a study by Leibniz-Institute of Freshwater Ecology and Inland Fisheries, it was found that Earthworms were changing their burrowing behaviour in the presence of microplastics, negatively affecting Earthworm fitness and soil condition. They can also impact abiotic elements of the environment, leaching heavy metals and other chemicals into the groundwater.

This is not to undermine the impact on human health. It is thought that microplastic ingestion can cause gastrointestinal distress, including irritation and abdominal pain. On top of this, microplastics can induce chemical toxicity, cause oxidative stress on airways and even damage mitochondria.

In a 2020 study, microplastics were even found in the placenta of four different women. Similarly, a 2022 study found that microplastic contamination was found in 11/13 tissue samples from surgery patients. The issue is becoming much more widespread, and cannot simply be brushed away, much like the microplastics that have caused this to begin with.

Infecting our environment

Microplastics can enter the environment from a variety of sources, none being natural. One of the biggest sources of microplastic contamination comes from plastic debris breakdown. Larger plastic items, including bottles, carrier bags and other single use plastics, break down over time due to exposure to sunlight and weathering processes. These fragmented pieces become microplastics in the environment.

Microplastics can also be introduced through personal care products. Prior to 2018, many hygiene products like exfoliating scrubs and toothpaste, contained tiny plastic particles known as microbeads. These microbeads were specifically manufactured and added to cosmetics to create a ball-bearing effect in creams and lotions. Unfortunately, these microbeads could not be completely filtered from the effluent, being deposited in the natural environment. Synthetic fibres also contribute to the problem. In fabrics like polyester and nylon, plastic microfibres are shed during washing, eventually making its way to rivers, lakes, and oceans.

Microplastics are even introduced from industrial processes and road runoff, where fragments produced during manufacture, processing or cleaning can be released. Similarly, vehicle tires and road paint can be washed into water bodies during rain, contributing to pollution.

Humans do not typically drink seawater, so it might seem strange to think that these microplastics could be ingested by us. One of the main ways that these microplastics enter our system is through the food chain, particularly through seafood.

Microplastics in the ocean are often mistaken for food by small marine organisms, thinking it small plankton or eggs. These smaller creatures can then be consumed by larger, moving up the food chain. This also leads to bioaccumulation of copious amounts of microplastics in the tissues of seafood, only to be ingested by humans further on. This also extends to filter feeders such as brachiopods and bivalves. By actively filtering microplastics along with plankton, accumulation of the particles occurs in the organism, making them a potential source of microplastic exposure for humans.

Unfortunately, this environmental contamination has even spread to controlled aquaculture environments. In fisheries globally, water which was previously free of contamination now introduces microplastics to farmed fish and seafood, which inevitably is ingested by humans upon consumption.

It might be wishful thinking to say that one could just avoid seafood, but the microplastic anathema has spread even further. Bottled beverages and plastic tea bags will continue to leach microplastics into the drinks. Processed foods have inexplicably been contaminated during processing or packaging. In fact, microplastics have even been detected in the air, especially in urban areas. People then ingest or inhale these particles, though the exposure is still being studied. It is even thought that humans may ingest anything from 0.1 to 5 g of microplastics weekly. That’s a grand total of 260 g annually, or just over 2.5 kg per decade.

Fighting back against microplastics

While the pervasive presence of microplastics in our environment presents a daunting reality, the urgency to combat this issue has never been clearer. With microplastics infiltrating our oceans, food, and even the air we breathe, finding sustainable alternatives becomes paramount. Biopolymers, derived from agricultural waste, are at the forefront of this eco-friendly revolution.

Biopolymers are eco-friendly materials made from natural, renewable sources, in this case agricultural waste and plant feedstock. In this way, monomers derived from the waste or feedstock, such as sugars, are reacted with renewable carbonylation agents from engineering materials, producing polycarbonates. By controlling the types of monomers used, ratios of different monomers and carbonylation agents, and modifying the molecule post polymerisation, the properties of the material can be tailored to a specific need. This biopolymer already finds usage in automotive manufacture and construction, but also as single-use packaging, medical devices and even as an additive to cosmetics. It is obvious to see that from a single technique, a potentially limitless variety of biodegradable plastics can be produced.

There are obvious environmental benefits to using this material. Of course, the overall waste from agriculture will be reduced dramatically, and the environmental burden of waste disposal will be heavily diminished. This also leads to economic advantages for any business adopting these materials. The first, for farmers, is the promotion of a circular economy, where even waste products can be potentially reworked into effective, high-quality products.

Further afield, it is thought that the reduction in waste disposal for businesses will produce cost savings, as well as meeting sustainability goals, promoting a positive brand image and appealing to environmentally conscious consumers.

Recognising the myriad benefits of biopolymers, it becomes clear that collaborative efforts and comprehensive support are essential to amplify their impact. Industries, policymakers and consumers are integral players in this transformative journey. Efforts have already been made to address the issue of plastic pollution, including the international Basel Convention treaty. The “Basel Convention on the control of transboundary movements of hazardous wastes and their disposal” is a treaty that regulates the transboundary movements of hazardous wastes, including certain types of plastic waste. Originally devised to prevent the dumping of waste in developing countries, it has since developed into a collection of covenants regarding a variety of waste, including plastic.

By controlling the movement of this plastic waste, especially in the form of microplastics from industrial processes, the convention helps prevent their proliferation in oceans and other ecosystems. Moreover, the treaty encourages international cooperation, allowing countries to work together to find sustainable solutions for the plastic waste crisis.

A brighter future

In the future, environmental policies are expected to continue to undergo significant transformations, reflecting a global commitment to combat plastic pollution. Governments worldwide are likely to adopt more stringent regulations on plastic production, usage, and disposal, aiming to reduce plastic waste at its source. This is already being seen with the EU’s ban on plastic glitter on October 17, with expectations that the restrictions will continue to tighten. International agreements and conventions like the Basel Convention will play a pivotal role in strengthening these efforts on a global scale.

Anticipated developments include the widespread implementation of Extended Producer Responsibility (EPR) programs, which will hold manufactures accountable for products throughout their lifecycle. EPR initiatives will incentivise eco-friendly designs, encourage the use of recyclable materials, and promote responsible waste management practices. These regulations will not only curb plastic pollution but also drive innovation, pushing industries towards more sustainable practices and fostering a cleaner, greener future for the planet.

In the hidden depths of our oceans, 4.5 million tonnes of microplastics silently weave their ghostly presence, haunting the very essence of our planet. As this spectral threat permeates our environment, a glimmer of light emerges in the form of biodegradable biopolymers.

The time has come to confront this unseen menace with action. Let us banish this environmental apparition by embracing the power of sustainable choices. Industries must innovate, policymakers must regulate, and consumers must demand eco-friendly alternatives. Together, we can dispel the ghost of microplastics from our oceans and usher in a future where the unseen no longer threatens our world. Join the movement, make the change, and create a future free from the haunting grip of microplastics.

To find out more about Tesha Technologies biopolymer technology and learn about some of its applications, visit the website.

Source: Water Magazine